Gartner predicts that by 2023, at least 50% of large global companies will be using AI, advanced analytics and IoT in supply chain operations. IoT devices have completely transformed Supply Chain Management both in terms of its operational efficiencies and revenue opportunities by making it more transparent. Modern supply chains not only enable you to keep track of your products but also allow you to gain an edge over your competitors. Leveraging IoT in supply chain management makes it much easier to locate your goods, track their movement, identify where and when they are delayed in transit and plan alternative routes, monitor their storage conditions (temperature, humidity etc.), and estimate when they will arrive at a specific location.

Applications of IoT in Supply Chain Management

Asset Tracking and Tracking

Traditionally, asset-intensive sectors like manufacturing, energy and utilities have been facing challenges with delayed product deliveries, inventory theft and loss and damaged goods. IoT devices and sensors replace traditional asset tracking methods like tracking numbers and bar codes, providing the ability to track and manage goods throughout the supply chain. IoT devices can identify where and when goods are delayed in transit allowing for contingency planning and alternative routes to speed up the supply chain. Businesses can also use these sensors to gain granular data like the temperature at which a product was stored, how long it spent in transit, and when it was sold. This type of data gained from IoT technology can help companies focus on quality control, on-time deliveries, and improve forecasting. Monitor transactions and movement of assets or goods across trading partners and organizations. With IoT asset tracking and blockchain-enabled tracing, you can create a digital trail of each step and securely record business transactions across your supply chain.

Forecasting and Inventory Planning

Many manufacturers and distributors are using outdated forecasting methods to develop business strategies. IoT sensors collect data on usage and buying patterns, giving product manufacturers the ability to evolve from traditional forecasting to planning based on actual consumption. Information is readily available for key decision making as you can track your inventory including existing supplies, at the click of a button. All this data which acts as inputs to advanced analytics can be used to discover trends and patterns to make manufacturing schedules more efficient, and making sure that brands sell as much as possible without oversaturating the market.

Real-time Visibility

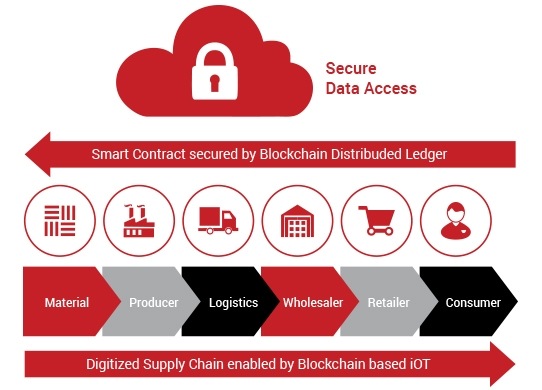

End-to-end visibility across supply chains is becoming increasingly complex due to the number of parties involved in global supply chains. In order to respond effectively to supply chain disruptions, companies should be able to validate and analyze data across the supply chain before they can respond. IoT devices can track the status of goods as they move through the supply chain and ensure that all parties in the supply chain are able to access the data in real time, track the status, prepare for shipping and execute transactions. All of this can be done via a combination of IoT and blockchain technology. This information can also be combined with third-party data sources, allowing companies to react quickly to unexpected supply chain events such as supply disruption or a sudden dip in customer demand.

Global Supply Chain Finance

Global supply chains typically include cross-border transactions, causing delays, because they involve multiple parties, international payments, local banking regulations, and heavy paperwork. Any discrepancies, such as duplicate invoices, can cause significant delays in clearing the payments. IoT and blockchain together could speed up the movement of goods across borders, resulting in secure, efficient, and cheaper transactions that prevent fraud through a distributed ledger that cannot be manipulated. With blockchain-powered smart contracts, companies can eliminate the need to reconcile documents across multiple parties. They can monitor the shipment status and execute the payment terms of the contract upon delivery.

Connected Fleets

While IoT can optimize the management of fixed assets such as machinery and equipment, it also improves the management of assets that are in motion – such as cars, trucks, ships, and autonomous vehicles. Ensuring that the entire fleet, be it shipping containers, suppliers’ delivery trucks, or your delivery vans are connected, allows you to gain better visibility into the supply chain, lowering transportation costs, increasing fleet efficiency, and improving customer service by ensuring on-time delivery.

Predictive Maintenance

Preventive maintenance seeks to decrease the likelihood of a machine’s failure by ensuring regular maintenance whereas IoT-enabled predictive maintenance leverages sensor data to determine the likelihood of equipment failure or breakdown before it occurs. With the ability to process large amounts of data and run sophisticated algorithms, IoT-enabled predictive maintenance allows companies to identify and predict potential failures before they occur and increase the productivity of critical assets. Companies can use IoT sensors in their high-value equipment and machinery to ensure timely preventive and predictive maintenance, avoiding unplanned downtime that increases costs.

Regulatory Compliance

In highly regulated industries such as food and pharmaceuticals, products need to be transported under strictly controlled temperature ranges and within specific time windows. Manufacturers and distributors need to be able to provide proof of compliance and failing to do so can cause high-value shipments to be delayed or seized by the authorities for investigation. An IoT and blockchain based framework can guarantee the reliability and security of information and provide evidence of regulatory compliance. Combining IoT and blockchain also enables suppliers to specify compliance conditions in a smart contract, ensuring the flow of reliable information across the supply chain.

Vendor Relationships

Supply chain management requires cooperation and collaboration between you and your vendors. IoT data allows companies to change business strategies quickly by modifying their own production schedules, and identifying underperforming vendors that are costing them money. You can analyze how your vendors are handling your supplies, and how they’re handling your product once it’s manufactured. Higher quality goods mean better relationships with customers and better customer retention overall.

Customer Support

IoT devices and sensors can be integrated with your applications, generating enough data to fundamentally change the nature of field service, customer support and end-user training. For example, rather than forcing a field worker to call a help desk when a piece of equipment fails, you can deploy IoT applications and solutions that enable the field worker to identify the issue and resolve it – in many cases without help desk intervention. That can reduce downtime and customer support costs while increasing user productivity. At the same time, companies can gather real-time data about the performance and reliability of their assets, which can be used to improve their design.