Maintaining quality targets is now one of the most challenging aspects that small to large scale industries face in the digital environment. Manufacturing test automation solutions are critical for ensuring product reliability and quality. It contributes to the company’s earnings and reputation while also ensuring that your items fulfill client expectations. Every manufacturing industry, from transportation, electronics, chemical industries, furniture & fixtures, fashion industries, and household goods to building materials, should invest in automated testing in production because it allows your team to meet increasing customer demands by producing high-quality products at reasonable costs.

Role of Manufacturing Test Automation in Ensuring Quality Control Throughout the Supply Chain

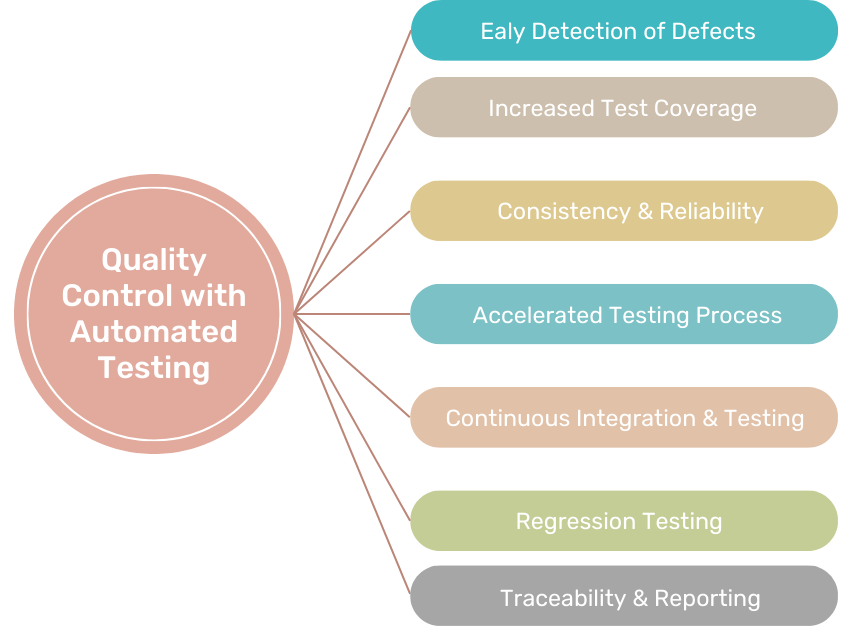

Automated testing provides a systematic and efficient approach to test various components, systems, and processes involved in the supply chain, thereby reducing the chances of errors, improving overall quality, and minimizing potential risks.

When you use software automated testing in production, you may minimize the time it takes to do repetitive testing from months to days and days to hours. Software tests are frequently repeated during development cycles to assure quality. When software checks in a recurrent activity, the source code is altered each time. Because of the human labor involved, this process takes a long time and costs a lot of money. Automated tests, on the other hand, are performed using automation technologies and save both time and money.

To increase manufacturing quality, some components of testing are totally automated, and operators do some repetitive testing operations of handling of parts, dealing with paper or electronic data sheets, reaction to failed components and ensuring the safety of both property and people.

When the test system performs harmful procedures under extreme conditions such as current, voltage, pressure, and temperature, the test system may control the connections and proximity events to safeguard humans from unanticipated incidents. Furthermore, the test system verifies the test conditions, depletes the system’s energy, and shuts down the unit activities to allow users to experience safety through test automation.

By leveraging manufacturing test automation, organizations can establish a robust quality control framework throughout the supply chain. It helps in mitigating risks, identifying defects early on, improving efficiency, and ultimately ensuring the delivery of high-quality products or services to customers.

Ensuring Transparency and Traceability of Products and Processes Through Manufacturing Test Automation

Automated inspection in manufacturing plays a vital role in ensuring transparency and traceability of products and processes throughout the supply chain cycle. It helps provide visibility into the quality and performance of various components, systems, and processes involved, enabling organizations to track and monitor their products’ journey and associated testing activities.

Here’s how manufacturing test automation ensures transparency and traceability:

- Test Case Documentation: Automated testing in production involves the creation of test cases that outline the expected behavior of the product or process being tested. These test cases serve as documented evidence of what has been tested and provide transparency into the specific requirements and functionalities being validated.

- Test Execution Logs: Manufacturing test automation generates detailed logs of test execution, capturing information about each test case, its status (pass/fail), and any associated errors or issues encountered during testing. These logs provide transparency by documenting the steps taken during testing and the outcomes obtained.

- Reporting and Metrics: Tools used for automated inspection in manufacturing offer reporting capabilities that generate comprehensive reports and metrics about the testing activities. These reports provide visibility into the overall quality and performance of products and processes within the supply chain. They can include information such as test coverage, defect density, test pass rates, and other key performance indicators, offering transparency into the testing progress and results.

- Integration with Test Management Systems: Manufacturing test automation can be integrated with test management systems, which act as centralized repositories for test artifacts and related information. Test management systems facilitate traceability by linking test cases to requirements, user stories, or other specifications, establishing a clear connection between the testing activities and the desired outcomes. This integration ensures that the testing process is well-documented and traceable.

- Version Control and Configuration Management: Frameworks of automated testing in production often leverage version control and configuration management systems to manage test scripts, test data, and related resources. These systems track changes made to test scripts, enabling traceability of modifications and ensuring that the correct versions of test assets are used during testing.

- Continuous Integration and Deployment Pipelines: Manufacturing test automation is often integrated into continuous integration and deployment pipelines, where code changes and updates are automatically built, tested, and deployed. This integration ensures that every change is thoroughly tested, and the associated test results are transparently captured. It enables traceability by linking code changes to specific test cases and their outcomes, facilitating visibility into the impact of changes on the overall supply chain.

How Manufacturing Test Automation Improves Collaboration and Communication in the Supply Chain

Automated testing improves collaboration and communication in the supply chain by providing a common framework and shared understanding of quality assurance activities.

Here’s how:

- Standardized Testing Process: Manufacturing test automation provides a consistent framework for planning, executing, and documenting tests, ensuring that everyone involved understands the testing procedures and requirements.

- Clear Test Case Specifications: Automated testing in production involves the creation of detailed test case specifications that outline the expected behavior and criteria for success. These specifications serve as a communication tool, clearly defining the scope of testing and the desired outcomes.

- Centralized Test Management: Automated inspection in manufacturing often employs test management systems that act as centralized repositories for test artifacts and related information. These systems provide a shared platform where stakeholders can access and collaborate on test cases, test data, test results, and other testing-related documents.

- Collaboration on Test Maintenance: Manufacturing test automation involves the creation and maintenance of test scripts and test data. This collaboration ensures that tests are continuously aligned with changing requirements and helps prevent communication gaps or delays.

- Shared Test Results and Reports: Automated testing in production generates comprehensive test reports and results that can be easily shared with stakeholders. These reports provide visibility into the quality and performance of products or processes being tested, promotes open communication and facilitates decision-making based on reliable testing data.

- Integration with Collaboration Tools: Automated inspection in manufacturing can be integrated with collaboration tools such as project management systems, issue tracking systems, and communication platforms. Integration with these tools enables seamless collaboration, discussing and addressing testing-related issues, tracking the progress of testing activities, and sharing important updates or notifications.

Manufacturing test automation ensures that all decision-making bodies are aligned, problems are addressed promptly, and the overall quality of products and processes is enhanced.