Key Takeaways

- CNC is now a strategic enabler of business continuity, not just a technical necessity.

- JD Edwards CNC Services must evolve to support hybrid, compliance-heavy, and automation-driven environments.

- Emerging trends in 2025: SRE-led CNC, cloud adoption, automation, compliance-first designs, and continuous Tools management.

- Enterprises still relying on traditional support risk downtime, rising costs, and compliance failures.

- Choosing the right CNC services partner is critical to future-proof JDE investments.

|

Why CNC Still Matters in 2025

In 2025, JD Edwards EnterpriseOne remains a critical ERP backbone for thousands of enterprises worldwide. While many organizations have modernized infrastructure, the CNC (Configurable Network Computing) layer still defines performance, scalability, and compliance.

Yet, the role of CNC has evolved significantly. Once viewed as a tactical IT function, it is now a strategic enabler of uptime, automation, and digital transformation. This is why demand for JD Edwards CNC Services has surged in recent years, because enterprises can no longer afford reactive, ticket-based CNC support.

What Are JD Edwards CNC Services?

JD Edwards CNC Services refer to the specialized expertise, monitoring, and management required to keep the CNC layer running at peak performance. These services include:

- Architecture & Components: Web, Enterprise, and Deployment servers

- Server Management: Monitoring, patching, and incident recovery

- Package Management: Builds, deployments, and upgrades

- Performance Tuning & Monitoring: Ensuring speed and resilience

- Database & OCM Configuration: Secure and scalable foundations

- Security Administration: Compliance-ready systems management

- Tools Release & ESU Management: Staying current without disruption

- Troubleshooting & Logging: Rapid root cause resolution

- Integration & Interfaces: Orchestrator, APIs, and third-party systems

Without robust CNC services, enterprises risk downtime, poor performance, and failed compliance audits.

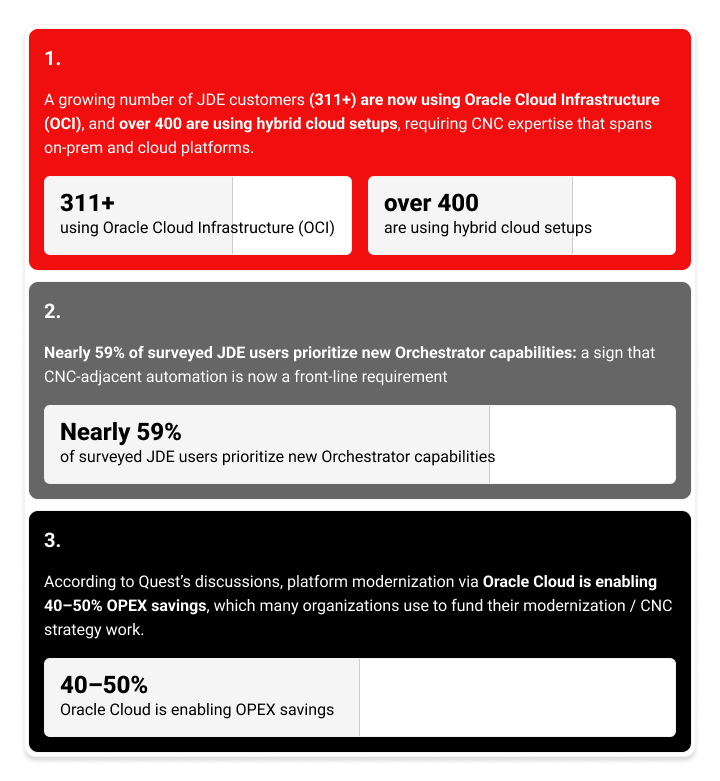

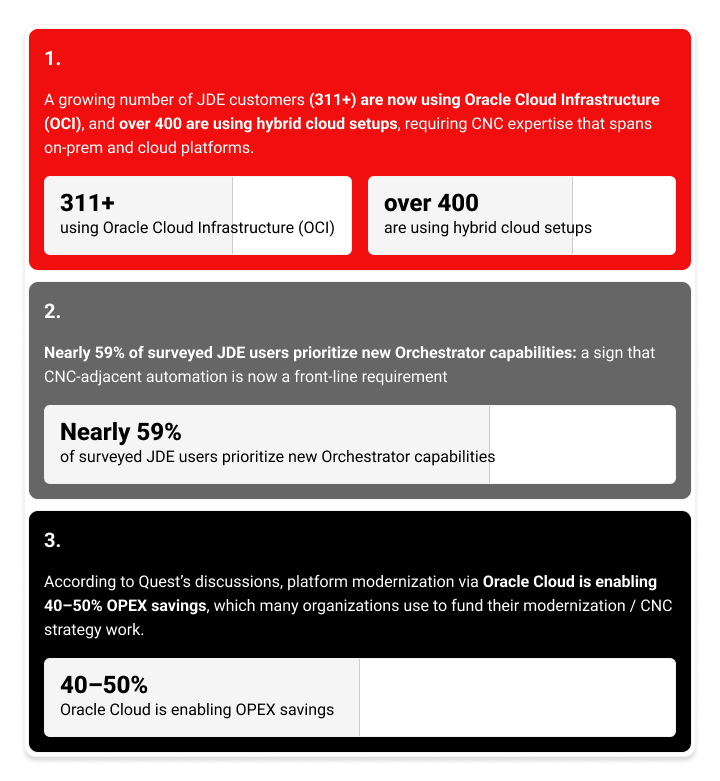

Key Stats Defining CNC in 2025

Recent industry insights highlight the growing demand for advanced CNC services:

A growing number of JDE customers (311+) are now using Oracle Cloud Infrastructure (OCI), and over 400 are using hybrid cloud setups, requiring CNC expertise that spans on-prem and cloud platforms.

Nearly 59% of surveyed JDE users prioritize new Orchestrator capabilities: a sign that CNC-adjacent automation is now a front-line requirement

According to Quest’s discussions, platform modernization via Oracle Cloud is enabling 40–50% OPEX savings, which many organizations use to fund their modernization / CNC strategy work.

These numbers confirm what many IT leaders already know: CNC is no longer just maintenance, it’s a driver of resilience and modernization.

Emerging Trends in JD Edwards CNC Services

Shift Toward Proactive, SRE-Led Models

Organizations are moving away from reactive ticket systems and toward Site Reliability Engineering (SRE)-led CNC services. This model emphasizes root cause prevention, optimization, and continuous improvement.

Rise of Hybrid & Cloud CNC Deployments

Running JDE on OCI, AWS, or Azure is now a mainstream practice. JD Edwards CNC Services in 2025 must support hybrid environments that combine on-prem, private cloud, and SaaS integrations.

Increasing Role of Automation & AI

Automation is central to CNC operations: orchestrator-driven builds, automated server recovery, RPA for repetitive tasks, and AI-enabled monitoring to detect anomalies.

Compliance-Driven CNC Strategies

As industries face stricter governance, CNC services are being redefined in terms of compliance readiness. That means documentation & best practices, audit logs, and secure system administration.

Tools Release & ESU Currency as a Service

Enterprises no longer want disruptive, CapEx-heavy upgrades. Instead, many rely on continuous Tools Release and ESU management built directly into CNC services contracts.

The Challenges Enterprises Still Face with CNC

Despite advances, many enterprises continue to struggle with:

- Outdated, ticket-based CNC support

- Unpredictable upgrade costs

- Lack of database & OCM configuration expertise

- Reactive performance tuning that only addresses issues after outages

- Minimal automation adoption in critical CNC workflows

- Shortage of specialized CNC skills in the market

Why Modern CNC Services Are Strategic, Not Tactical

Today, CNC is no longer “just IT plumbing.”

It ensures:

- Business Continuity: No tolerance for downtime in 24×7 operations

- Scalability: CNC must evolve with business growth and integrations

- Cost Efficiency: Predictable monthly fees replace costly, reactive fixes

- Innovation: Automation and AI readiness support future transformation

Enterprises now consider JD Edwards CNC Services a strategic investment, not an operational expense.

How Organizations Are Preparing for the Future of JD Edwards CNC

Leading JDE enterprises are:

- Embedding performance tuning & monitoring into daily operations

- Automating builds, deployments, and server management

- Partnering with vendors who provide JDE CNC managed services across cloud, on-prem, and hybrid setups

- Prioritizing security administration and compliance alignment

- Leveraging predictable funding models like “Playing the Bank” to stay current without CapEx spikes

What to Look for in a CNC Services Partner in 2025

When evaluating Oracle JDE CNC service providers, look for:

- Proactive, SRE-led support model

- Experience across hybrid and cloud-hosted CNC environments

- Deep skills in package management, integration, and logging

- Proven compliance expertise (SOX, SOC-2, CFR Part 11)

- Pricing transparency with built-in flex hours for emergencies

- Automation-first capabilities with Orchestrator, RPA, and AI

Future-Proofing JD Edwards with Smarter CNC Services

The state of JD Edwards CNC Services in 2025 is defined by one reality: reactive models can no longer sustain modern ERP ecosystems. Enterprises need proactive CNC services that prevent downtime, enable compliance, and leverage automation to reduce costs.

By partnering with the right CNC services provider, organizations can not only protect their JDE investments but also accelerate modernization, unlock performance, and ensure their ERP is ready for the next decade of change.

The state of JD Edwards CNC Services in 2025 is defined by one reality: reactive models can no longer sustain modern ERP ecosystems. Enterprises need proactive CNC services that prevent downtime, enable compliance, and leverage automation to reduce costs.

By partnering with the right CNC services provider, organizations can not only protect their JDE investments but also accelerate modernization, unlock performance, and ensure their ERP is ready for the next decade of change.

Frequently Asked Questions (FAQs)

- Why is CNC critical in JD Edwards today?

Because CNC governs performance, security, scalability, and compliance across all JDE EnterpriseOne components. Without strong CNC, business continuity suffers.

- What are the limitations of traditional CNC support?

It’s reactive, staff-rotated, lacks automation, and often delays Tools and ESU upgrades, causing downtime and compliance gaps.

- How have JDE CNC requirements changed in 2025?

Hybrid cloud deployments, complex integrations, tighter compliance (SOX, GDPR), and higher user expectations demand proactive CNC support.

- What should I look for in a CNC services partner?

Proven JD Edwards CNC expertise, automation capabilities, SLA-backed services, and experience in Tools management.

- What’s the value of moving to proactive CNC support?

It reduces downtime, ensures compliance, keeps JDE current, and provides strategic optimization instead of just issue resolution.